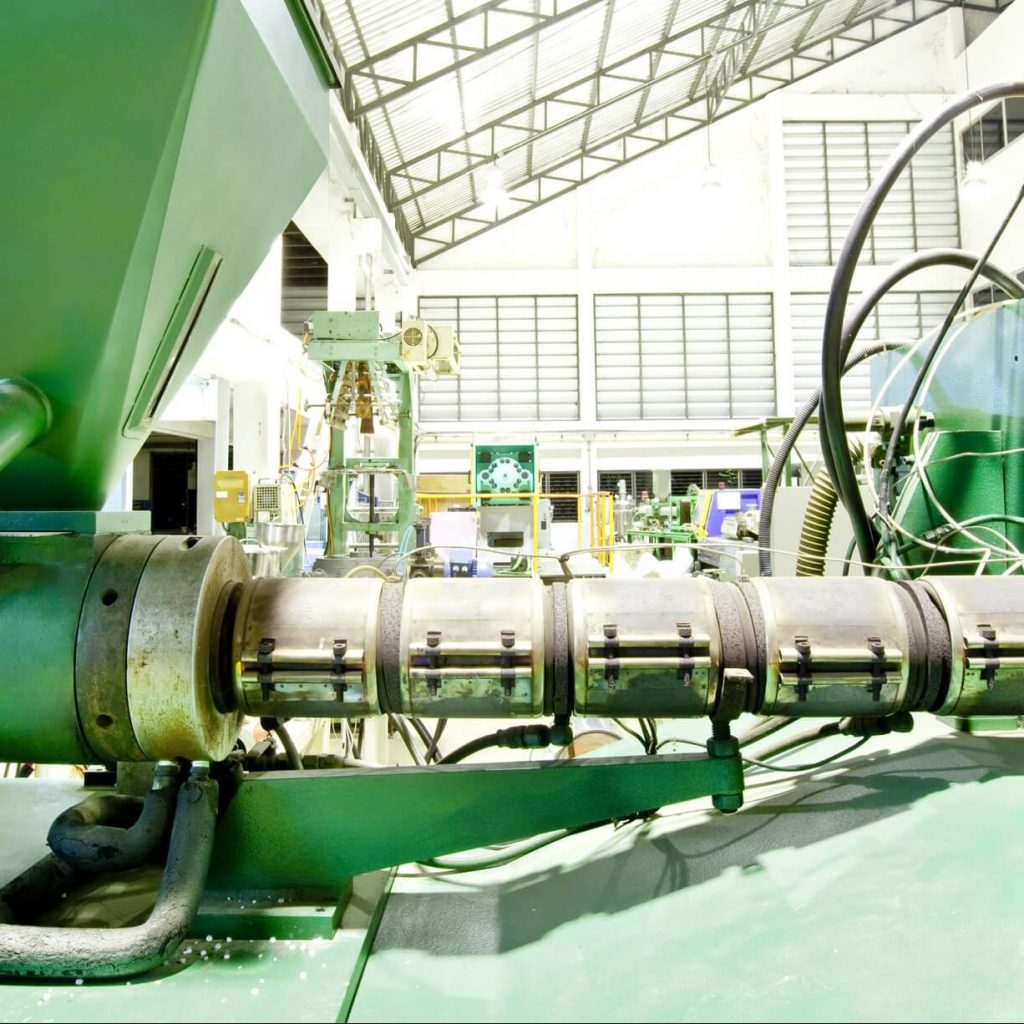

Hydraulic Cylinders

Market leading innovations with hydraulic cylinders

Our Experience with Hydraulic Rams

Whatever the sector or field from offshore mining to steel manufacturing Apex commits to producing Hydraulic Cylinders / Hydraulic Rams that will outperform those of our competitors

When it comes to Hydraulic cylinder design and manufacture Apex Hydraulics are at the forefront of the UK industry. At Apex we understand the crucial role Hydraulic Cylinders play in today’s leading industries. For this reason we insist on making excellent service, high quality products and skilled craftsmanship foundational to our ethos. Whatever the sector or field from offshore mining to steel manufacturing Apex commits to Hydraulic Rams that will outperform those of our competitors. Our bespoke design service provides individual solutions for your specific requirements whilst our highly efficient processes ensure we deliver excellent lead times saving you costly downtime.

HYDRAULIC RAMS DESIGNED BY THE EXPERTS

Apex’s comprehensive bespoke design and manufacture service means our expert team will tailor a cylinder that will meet your exact specifications and will best serve the required application. Our design team is ISO 9001 certified, which means we are able to carry out modifications to improve existing hydraulic ram designs so you are never restricted to a set design or standard model. Excellence and innovation are at the core of Apex’s expert technical team; the result is exceptional service every time.

Apex Hydraulic Cylinder Expertise Put to the Test

As a leading hydraulic cylinder manufacturer, we understand the arduous conditions much of your Hydraulic equipment has to endure. High usage and harsh environmental conditions both contribute to the pressure many hydraulic rams face. Impact, corrosion, wear and galling are common causes of damage and failure, even where traditional Hard Chrome Coatings (HCCs) have been applied for protection. As a solution here at Apex we have developed our own superior solution to HCC, Corex. COREX coating is exclusive to Apex and is proven to outperform traditional HCCs, increase cylinder life and minimise potential damage.

- Every ram is tailored exactly to your specific requirements

- We never ‘make fit’ an unsuitable cylinder because it’s from our standard range

- Rams are available with a variety of valve applications

- Innovative protective coatings are available for critical rams and those under harsh conditions (COREX)

- Different paint specifications are available to suit the cylinder’s environment

Rams are available with a variety of valve applications

Full ‘test and certificates of conformity’ are available should you need them. We can also manufacture rams with third party approval certificates such as:

- DNV GL (Det Norske Veritas) DNVGL-CG-0194 (formerly standard for certification No.2.9)

- ABS (American Bureau of Shipping)

- Lloyds Register

- ISO 9001:20015

Frequently Asked Questions…

Yes, we can manufacture any type of cylinder. If you give us the specifications we can make one that is exactly the same. If you don’t know the specifications then if you give us the part to examine we can engineer one that is identical. In addition, our designers may be able to suggest design improvements on your current model, or offer superior coatings or seals. This will all be discussed with you during the design process.

We specialise in all sizes of bespoke cylinders; large or small. We design anything from small cylinders for factory machinery or vehicles, right up to huge cylinders for the off shore industry. We are able to do runs of multiple cylinders at a time, or just a single cylinder. We are happy to facilitate whatever requirements our customers have.

Yes! We specialise in re-engineering things to work well. We find that many manufacturers do not over engineer things first time around and that many hydraulic cylinders are made to minimum requirements. This means that when they meet the harsh environments found in many industries (excessive heat; saltwater; being chipped by stones or debris), they are not fit for purpose for as long as was hoped. At Apex, we have been working with hydraulics from every industry for many years. We know what is effective and what isn’t and we know what challenges hydraulic systems face, according to which industry they are exposed to. We can then design a system that will work well for your specific needs in order to increase the cylinder’s durability and robustness. Our design team work together with our machine shop and inspection department to ensure that every piece of equipment that leaves our workshop is of an exceedingly high standard in order to be able to meet the demands of gruelling working environments.

Yes, we often work together with manufacturers to ensure that our hydraulics fit the fabrication that is being built. We are happy to advise on the design of a fabrication with regards to the internal hydraulics. However, if the fabrication is already in existence, we can also design our hydraulics around the machinery that you already have in place.

No, we specialise in the manufacture and repair of bespoke cylinders. We can always design something to your exact requirements, so if you have a standard cylinder size in mind we are happy to take those specifications and design something of high quality and durability to fit your required fabrication exactly.

We are usually able to manufacture new cylinders in 4 to 8 weeks. However, we understand that under some circumstances, new hydraulics are required urgently. Depending on the job, we have on occasion manufactured a new cylinder through the stages of design, manufacture, inspection and dispatch with an even shorter turnaround than four weeks. Please call us if you wish to discuss your individual requirements.

Yes, we ship our bespoke hydraulics worldwide. We communicate by e-mail and Skype and are not deterred by very different time zones! We are happy to facilitate visits from third party inspection agencies where relevant. Where necessary we can also travel to you to ensure that the hydraulics are correctly installed and working properly, though in most cases, careful communication with your own engineers makes the process trouble free.

We specialise in both the manufacture and the repair of hydraulics. Our technicians are happy to discuss your needs with you and advise on whether repair or replacement is better for your specific requirements. We have yet to find a hydraulic cylinder that we cannot repair and we are always happy to restore one for a customer. However, there are occasions where it is more efficient if we replace a cylinder rather than repair it.

Dirty oil can cause massive problems in any hydraulic system, and we recommend ensuring that oil is well filtered in order to avoid expensive repairs and large amounts of down time. One of our main services is in providing excellent oil filtration rigs that can be fitted to almost any existing hydraulic system in order to keep the oil clean and well filtered. Filter changes are easy, making them inexpensive and reducing down time.

Hydraulic Rams: Innovative Industry Solutions

Our commitment to excellence and client satisfaction means every hydraulic ram produced at Apex is rigorously tested according to our customer’s requirements. If you would like more information on our testing procedures or would like to witness them first-hand please contact us. You are invited to come along, either with a verification body or simply to see our technical team in action.

Hydraulic Cylinder Repair & Manufacture

We manufacture and repair hydraulic rams to suit the individual requirements of our clients.

Here is a selection of the range of products we provide & associated repair services:

|

|

For those wishing to find out more general information about Hydraulic Cylinders we have created a Guide to Hydraulic Cylinders that walks you through the main aspects of a Hydraulic cylinder and the different types available.

Gallery

Please find related images below…

Related Case Studies for Hydraulic Rams / Cylinders

Read more about our experience with hydraulic rams within the case studies below

Related Sector Experience for Hydraulic Cylinders / Rams

Read more about our sector experience associated with hydraulic cylinders below

Latest News

Read more about our latest news below