Hydraulic Cylinders Lock Subsea Mooring Mechanisms

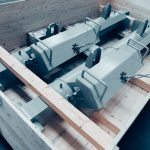

Apex was commissioned to manufacture a number of bespoke hydraulics for a company specialising in subsea connectors

THE PROJECT

Apex was commissioned to manufacture a number of bespoke hydraulics for a company specialising in subsea connectors. These cylinders provide a locking and unlocking mechanism for a subsea mooring connector, that can be used to moor a variety of huge offshore fabrications; from giant Floating Liquefied Natural Gas stations, to underwater kites – used to produce renewable tidal and ocean current energy.

The hydraulics are used to make the locking fingers extend, linking securely to the load shoulder that is embedded in the floor of the sea. The lock produced by the hydraulic system needed to be able to hold up to 1000 tonnes, working under a pressure of up to 210 bar, with a stroke time of 20 seconds. Crucially, in spite of remaining motionless after the initial locking process, the hydraulic system had to remain fully functional in order to be able to be unlocked again after a number of years.

THE CHALLENGE

Any subsea project needs to take into account the huge pressures that arise when working at great depths. Every ten metres below the surface of the sea, there is an additional one bar of pressure placed on a fabrication. This means seals need to be in outstanding condition, to avoid the pressure allowing sea water to push its way into the cylinder, contaminating the hydraulic fluid and causing system failure. In this case, the fabrication was to be placed at an approximate depth of 60 metres.

In addition, under this intense pressure, the hydraulic cylinder needs to be capable of unlocking the mooring, as well as locking it. This means that the same force must be exacted on both the push and the retract of the cylinder rod.

While the mechanism needed to move into a locking position only once, the real challenge of this project was that the lock needed to be capable of staying securely in place for up to 25 years, and then to be in perfect working order decades later, when it is required to be unlocked for removal.

This means that the hydraulic cylinder needs to survive for a quarter of a century without corroding, or being so engulfed by marine growth that it becomes immovable.

THE SOLUTION

Initially, the Apex design team needed to establish the tonnage that would be running up and down the mandrels and work from there; designing a hydraulic system that would be able to carry and hold the force required. There was a specialist design produced, comprising of a dual rod. This is a cylinder with one rod which goes all the way through the cylinder so it can advance and retract with the same force. A cylinder that can push with 100 tonnes of force, but retract with only 50 tonnes would have been no use for this project.

The thick body of the outer mandrel was forged from AISI 4340 Forging steel. This was coated in a specialist Everslick coating which contains an epoxy resin throughout the layers, giving it an outstanding resistance to corrosion and abrasion. This coating also has a solid lubricant in the top coat, creating a very low friction and so is ideal for use in interior stainless steel valves.

The rods were made from 174PH Stainless Steel and were coated in Apex’s own specially developed Corex coating. With a hardness of over 1400Hv, it is almost double the hardness and bond strength of standard Hard Chrome Plating, and around 5 to 10 times less porous. Because of these unique properties, this innovative coating is completely resistant to corrosion for the duration of the rod’s exposure underwater and beyond. In addition, the by-products of its production are far less environmentally damaging than HCP.

Highly specialised seals were used, that will stop salt water from entering, even under tremendous sea water pressure. They are also strong enough to scrape 25 years’ worth of marine growth off the rods as they retract, without the seals becoming damaged.

PEACE OF MIND

Having created the design, the products were manufactured in our highly-specialised Dewsbury workshop, overseen by experienced foremen. All hydraulics built at Apex are produced within the highly stringent Pressure Equipment Directives. After production, the hydraulics underwent a rigorous inspection process in our own independent inspection department. The cylinders were tested for sustained periods at pressures of 1.5 times the requested maximum working pressures. We carried out magnetic particle inspections and liquid penetrant examinations in accordance with all relevant protocols and regulations. Our clients were invited across to witness the pressure tests and we were happy to work together with their third-party inspection agencies to facilitate their own non-destructive ultrasonic tests.

Apex understand the need for all subsea hydraulic cylinders to be bespoke, robust and of exceptional quality, functioning perfectly from first use to the end of extremely long life spans. We are also happy to work together with clients to meet deadlines and will work to any inspection criteria necessary.

Contact Apex today on 01924 456788 with any enquiries about Subsea hydraulic systems.

The Sectors

We have strong experience working across a variety of different sectors. If you would like to read more about our sector experience associated with this project – click an image for more information….

Related Products

The following products were utilised as part of this project. For more detailed information on these products, click on an image below…