A Day in the Life of a Spray Painting Operative

Rob Hawkins

Rob Hawkins is the primary Spray Painting operative at Apex hydraulics. He has been with Apex for 15 years and during this time he has worked in the Strip and Assessment department, Welding workshop and the Inspection department. Now he splits his time between assisting in the Inspection department and being the main Spray Painting operative.

Painting hydraulic equipment is a precise art and each job needs to be carried out to exact specifications. Its importance is in ensuring that the system does not rust, so the paint work needs to be accurate. Different industries have different requirements. As in most areas of hydraulic design, off-shore rigs and ships demand particularly specialised products, as they are subject to such harsh environments and can therefore be inclined to rust and decay.

Rob starts his day meeting with Richard, the works manager, who gives him the specifications for each job and then prioritises the tasks for the day.

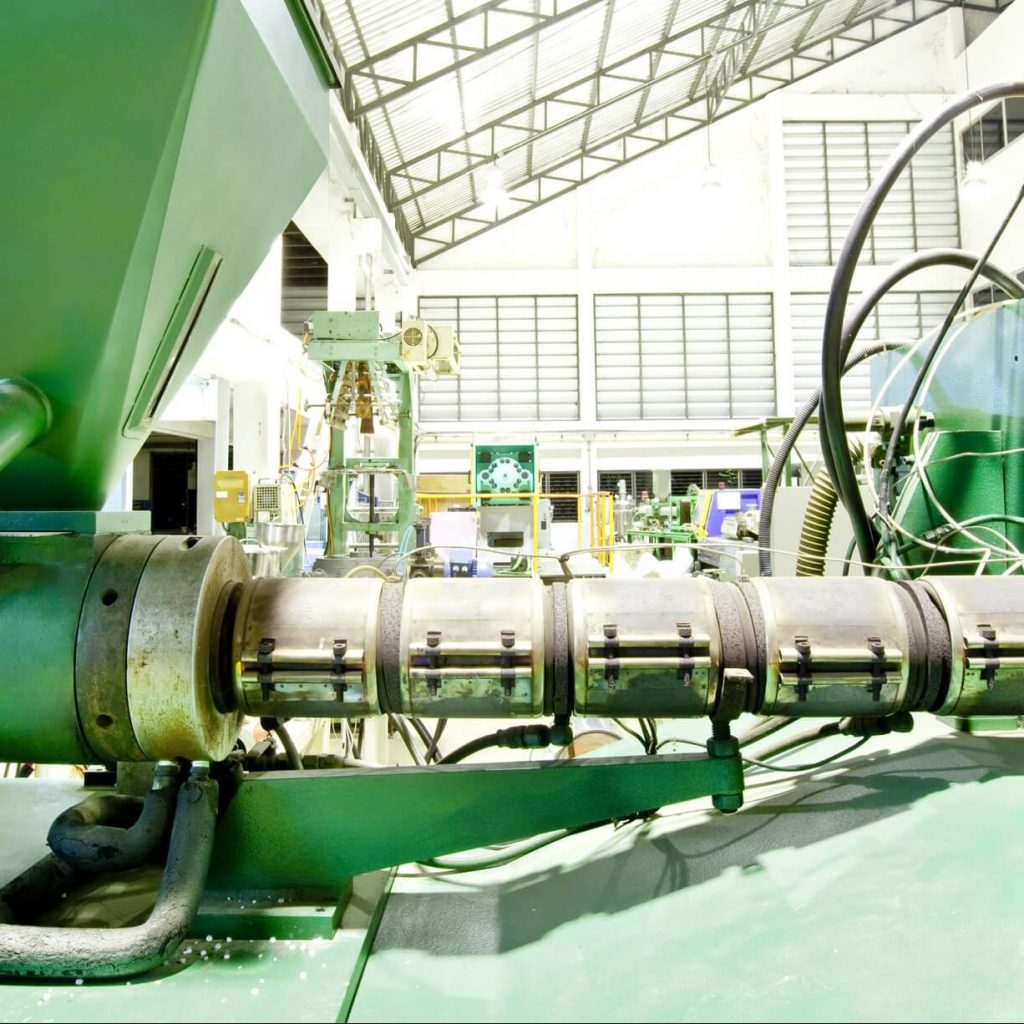

When Rob starts work on a hydraulic cylinder, health and safety is paramount, with mask and goggles being worn at all times. Each cylinder needs to be extremely clean and will have been shot blasted by the fitting department prior to painting to ensure that there are no remnants of grease on the cylinder.

Even small cylinders are too heavy to be lifted by hand, so an overhead gantry crane and swing jib hoists manoeuvre the cylinders into place in the painting area. They are hung on trestles straight after being shot blasted.

Each cylinder has an under coat, mid coat and top coat. The thickness of paint on each coat needs to be notarised. Rob uses a digital coating thickness gauge to measure the thickness over several points and takes the average. The customer stipulates the required thickness for the paint. The standard is between 30 and 100 microns for the first coat, 140-300 for the second coat, while the top coat is usually between 30-125. Paint is sprayed onto the body of the cylinder, but is brushed round the bolts and welds. This keeps the cylinder water tight and prevents rust. Sometimes the clients specify a paint brand or type. Apex is always happy to advise on the best paint for a particular job, and the works manager will confirm which paint type is required, along with the necessary thickness of the paint.

As with his colleagues in other departments, Rob appreciates the diversity of projects that he is involved with, from off-shore cylinders, to hydraulic arms for skip lorries;

“It’s unusual – you never know what type of job you’re going to get.”

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…