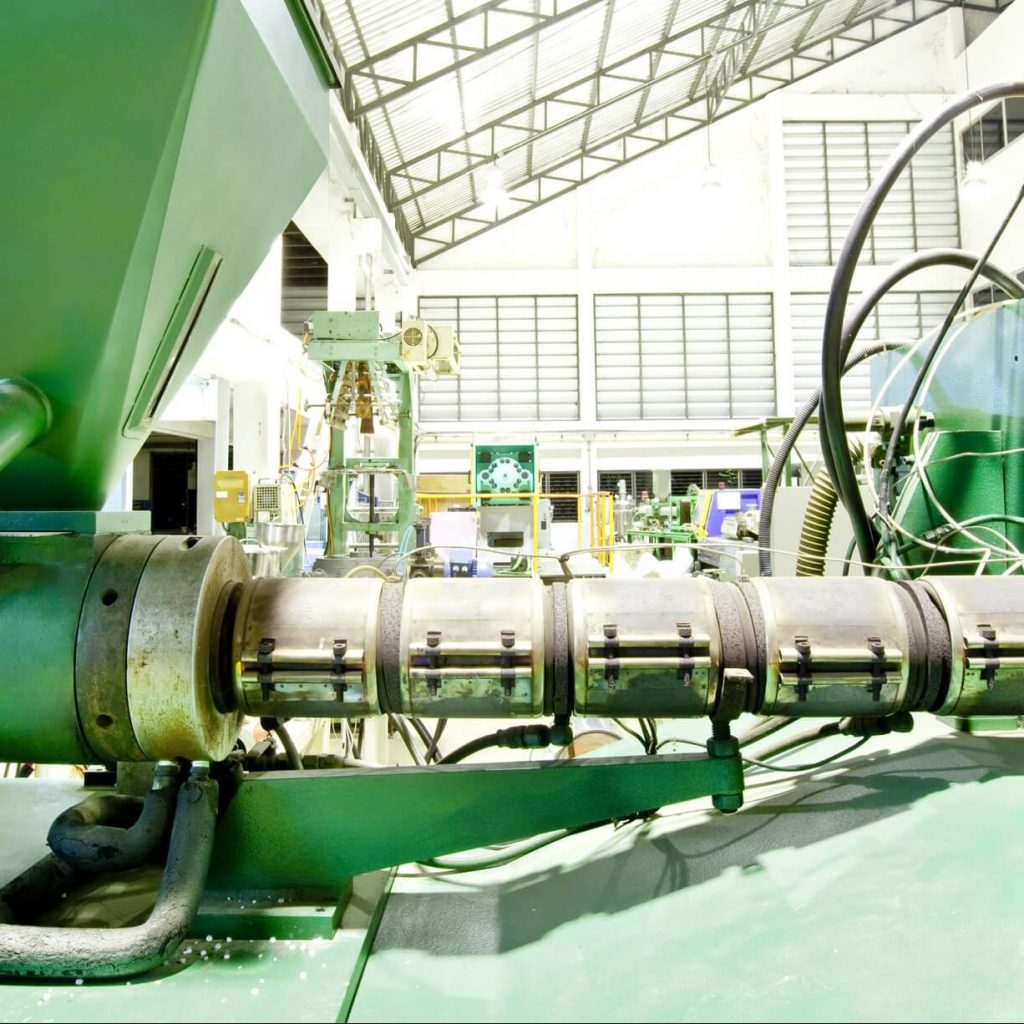

HYDRAULICS CYLINDERS: BESPOKE OR OFF-THE-SHELF?

When manufacturing a piece of equipment that requires a hydraulic cylinder, you’ll need to consider whether to install a standard catalogue cylinder or commission a bespoke design. When you buy a catalogue cylinder, it will always only be the nearest thing available for your requirements. This means that your fabrication design may require some compromise, in order to fit the cylinder. Alternatively, a bespoke cylinder will be manufactured entirely to your requirements, giving you the freedom to build your fabrication wholly fit for purpose.

COST IMPLICATIONS

While a standard, catalogue cylinder is always only going to be the “next best thing”, there may be circumstances when this will be sufficient; on a piece of low grade equipment that is not designed for longevity for example.

When you are designing a new piece of equipment, it is possible to design the fabrication around a standard cylinder. Some people may think that this is more cost effective than commissioning a bespoke cylinder. However, it is important to realise that this method is not always cost effective, as it is likely that you will have to compromise your design, possibly making it less efficient.

In most circumstances, Apex Hydraulics can produce a cylinder for an equivalent or lower price than an off-the-shelf item. Over Engineering is expensive, so a design that meets your requirements is far more efficient. In addition, the need to make a costly adjustment to your fabrication is eliminated by commissioning a bespoke design. Some custom-made high-end solutions can initially appear expensive, but these costs are soon cancelled out by extending service periods and improving ease of maintenance.

WOULD A BESPOKE DESIGN WORK FOR YOU?

A bespoke design can work for any fabrication design requiring a hydraulic cylinder. You can design your fabrication and then hand over the design of the cylinder to an expert team of hydraulic cylinder engineers, specifying your necessary stroke length, material, durability, pressure and any other requirements. Specialist seals can be used, depending on the application, environment and hydraulic fluid type. Cylinders can be designed to work under huge subsea pressures, high temperatures or low temperatures. They can be produced to be extremely durable to survive repetitive, high intensity strokes; or for the longevity required to stay in the advance position for decades before retracting.

Below are a number of features that can be adapted to your specifications in a bespoke cylinder:

• Mounting interface / styles

• Pin Location

• Space limitations

• Materials

• Seals

• Working pressures

• Material requirements & origin

• Design specifications

• Integrated functions

• Manifold blocks

• Stroke length

• Port locations

THIRD PARTY APPROVALS

Most standard cylinders do not come with the third-party approval that is necessary for equipment across many sectors. In particular, the offshore and marine industry requires all machinery to be built and tested to specific criteria with stringent evidence of manufacture and testing to prove its safety. Bespoke cylinder manufacturers can produce cylinders to whatever design criteria your third-party insurance company requires, offering certificates of conformity as well as facilitating independent testing (or the witnessing of in-house testing) by your third-party agents.

CYLINDER PRESSURES

When you are buying a standard cylinder for your design, one issue will be that you have to pick the “closest” pressure cylinder for your requirements. Inevitably, this usually means that they will either be over-engineered (and thus more expensive than necessary) or under-engineered (potentially dangerous if a low-pressure cylinder is constantly being used at the top of its working capabilities). The better option is to have a cylinder engineered to the exact pressure requirements of your product.

MAINTENANCE COSTS & DOWNTIME

One expensive aspect of hydraulic cylinder maintenance is the downtime required to service or repair machinery. If your business is relying on constantly working machinery, then several hours or days without the equipment in use can be very damaging. A standard cylinder will come with ports, pins, seals and filters that may not be easily accessible, making services expensive and long winded. Bespoke cylinders can be specially designed with areas that require regular services to be fully accessible. Certain equipment can even have specialist Bypass Filtration Units that require almost zero downtime for the changing of filters.

APEX EXPERT OPINION

At Apex Hydraulics, it is our opinion that if you are designing a piece of bespoke equipment, then the long term cost-efficient option is to have an expertly designed cylinder to fit your machine. This will increase the longevity of your machinery, as well as allowing it to work at its full potential with less downtime for maintenance and no risk of breakdown due to under-engineering. At Apex, we believe that you should be able to design a fabrication exactly the way you want – and then benefit from a bespoke hydraulic cylinder without having to compromise any aspect of your design.

If you are interested in discussing requirements for your own bespoke hydraulic cylinder design, call Apex today on 01924 456788 or e-mail sales@apexhydraulics.co.uk.

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…