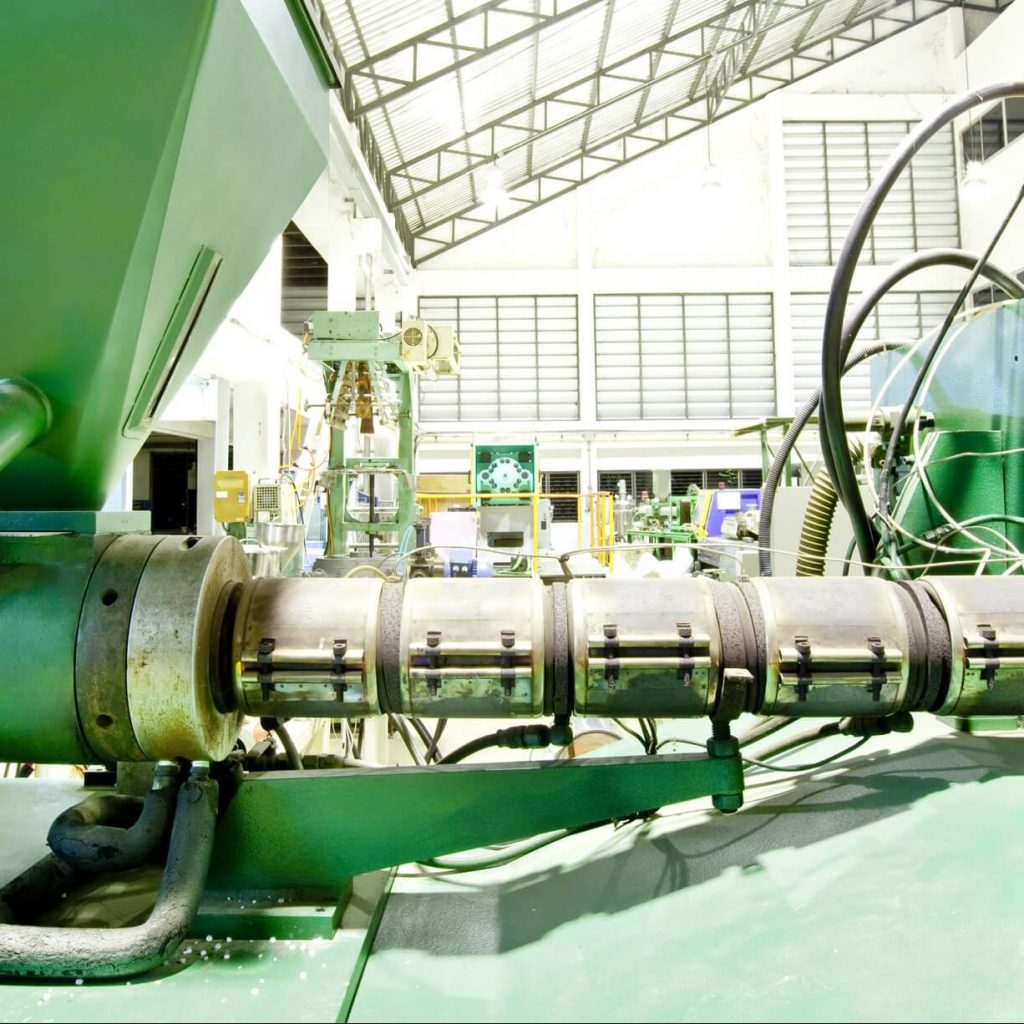

Should you Repair or Replace your Failing Hydraulic Cylinder?

Apex Hydraulics are sometimes asked whether it is more efficient to repair a hydraulic cylinder or replace it with a better one.

In many cases, the answer would be “repair.”

Certainly, in the case of premature failure, it is not economical to replace a cylinder like-for-like. After all, the cylinder has failed for a reason. Often Original Equipment Manufacturer (OEM) parts are made only “just” fit-for-purpose, with no over engineering. The main aim will be to produce hydraulic cylinders in bulk, in a cost-effective way, minimising materials. This often means that, while the parts are technically suitable, any additional strain that is put on the machinery can cause the parts to wear out quickly, reducing the longevity of the hydraulic cylinder. Because of this, a direct replacement of the OEM cylinder is likely to fail again in the same way.

There is no point in replacing a cylinder with another one without understanding exactly what went wrong with the original. Because of this, Apex requests that all original parts be brought to our state-of-the-art workshop, for strip and assessment. This allows Apex engineers to be able to identify the issues that are causing the hydraulics to fail. With this information, engineers are able to design a repair that addresses these issues, extending the longevity of the cylinder. Sometimes this may be a small issue, meaning that a single replacement part can entirely resolve the problem.

In other situations, there may be a failure of the hydraulic cylinder components meaning that the majority of the hydraulic cylinder requires replacing. However, even if 90% of the parts need replacing, there may still be one or two that can be used on the repair. Some undamaged items may be expensive to manufacture new, making the salvaging of these parts economically practical. There is usually at least something that can be kept from the old cylinder when carrying out a cylinder repair.

There are a number of items that may need attention in a hydraulic cylinder repair:

- The hydraulic rod: In some cases this may need to be strengthened. For example, Apex have recently worked on a telehandler that has experienced issues with the rod bending under excessive pressure. Because the rod bent, the plating becomes chipped and damaged, causing seals to split and break. Apex used a stronger hydraulic rod, with a more durable hard chrome plating, making it less likely to pit and chip. They also re-engineered the neck gland and piston to absorb some level of bend to the rod.

- Seals: Seals are not always selected fit for purpose. They are a sometimes seen as an expendable item within a hydraulic system, being a relatively inexpensive part. However, once seals are damaged, dirt enters the system, eventually causing complete cylinder breakdown and potentially expensive service costs. In addition, the downtime and labour costs involved with replacing a seal mean that it is financially more practical to repair a cylinder with seals that are more durable. Seals have been designed that can resist very high or low temperatures, or high stroke repetitions, making them more durable and increasing the longevity of the hydraulic cylinder.

- Filtration: While not technically a repair, advanced filtration systems can massively increase the life of your hydraulic system, as well as extending the amount of time required between internal filter changes. Therefore, if you find that filters are regularly becoming clogged and need replacing, a bypass filtration unit may resolve this quickly and efficiently.

If you have a faulty cylinder and are considering repair or replacement, speak to Apex Hydraulics today to discuss the best options for you.

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…