When to Request Expert Assistance

Once you have a maintenance plan in place and have scheduled regular services with experts, it can be tempting to relax into letting your hydraulic system look after itself.

Regular Checks

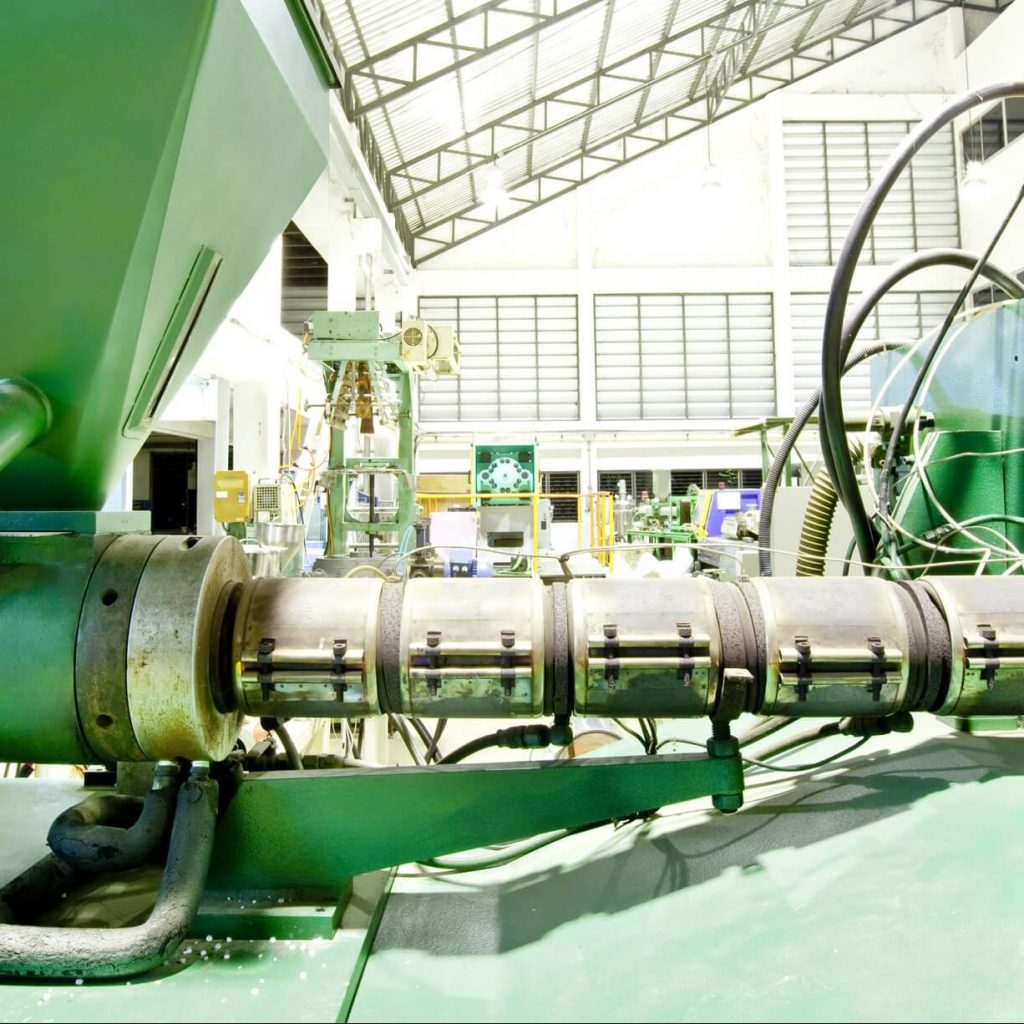

However, it is important to keep regularly checking your equipment to ensure that repair is not necessary. Expert assistance must be requested at the first sign of any problems. Anything out of the ordinary in your hydraulic system should be swiftly assessed by specialists; the system working more slowly than usual, noises, leaking oil and the system overheating are a few examples. If the tank or the power pack of your hydraulic system becomes hotter than usual, it is indicative that there is extra friction within the system and that something is amiss. This needs investigating quickly before causing further damage. We recommend that you call experts for advice if you notice anything unusual in your hydraulic system; do not wait for the next routine service.

Oil Quality

Possibly the most important aspect of preventative maintenance is in paying close attention to the state of your oil. Up to three quarters of faults in hydraulic systems are caused by problems with the hydraulic fluid. Oil samples must be taken regularly and sent to a lab to be checked.

It is easy for particles of dirt to enter your hydraulic equipment,both through routine use and basic errors. The financial effects of dirt in the system can be extremely significant, as well as there being potential safety repercussions when the dirt particles cause the equipment to malfunction.

Wear and Contamination

The lab tests will indicate whether your oil has become contaminated with dirt or water; if so, measures will have to be put in place immediately, rather than waiting for the next scheduled service. Particles of dirt in your hydraulic equipment will vastly reduce the life of the whole system. For example, an over-clogged filter can cause massive damage by releasing a collection of dirt all at once. Therefore it is vital that when the oil starts to show signs of wear and contamination, that the filters are changed to avoid other parts of the system becoming unusable.

An examination of the oil’s wear can also be a sign of whether there is corrosion in other areas of the system.

Machine lubrication technician, Bennet Finch, points out that an analysis of the oil’s wear can indicate whether the machine is “degrading abnormally.” It can also identify “from which internal component is the wear likely originating,” and “what is the wear mode and cause.”

Therefore a study of the wear can allow an early diagnosis of other faults in the system which can then be rectified before there is a full break down.

For a more in depth explanation of oil analysis, see our article on “Analysing and Maintaining Your Hydraulic Oil.”

For more information on how oil analysis can help us to keep your system running smoothly, contact APEX on 00 44 (0) 1924 456788 or use our contact form here.

Health and Safety Executive. [no date]. Provision and Use of Work Equipment Regulations 1998 (PUWER) [online]. Available from: http://www.hse.gov.uk/work-equipment-machinery/puwer.htm [Accessed 22nd October 2015].http://www.hse.gov.uk/work-equipment-machinery/puwer.htm

Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 199.

Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 199.

Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 200.

Health and Safety Executive. [no date]. Provision and Use of Work Equipment Regulations 1998 (PUWER) [online]. Available from: http://www.hse.gov.uk/work-equipment-machinery/puwer.htm [Accessed 22nd October 2015].

6 Health and Safety Executive. [no date]. Provision and Use of Work Equipment Regulations 1998 (PUWER) [online]. Available from: http://www.hse.gov.uk/work-equipment-machinery/puwer.htm [Accessed 22nd October 2015].

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…