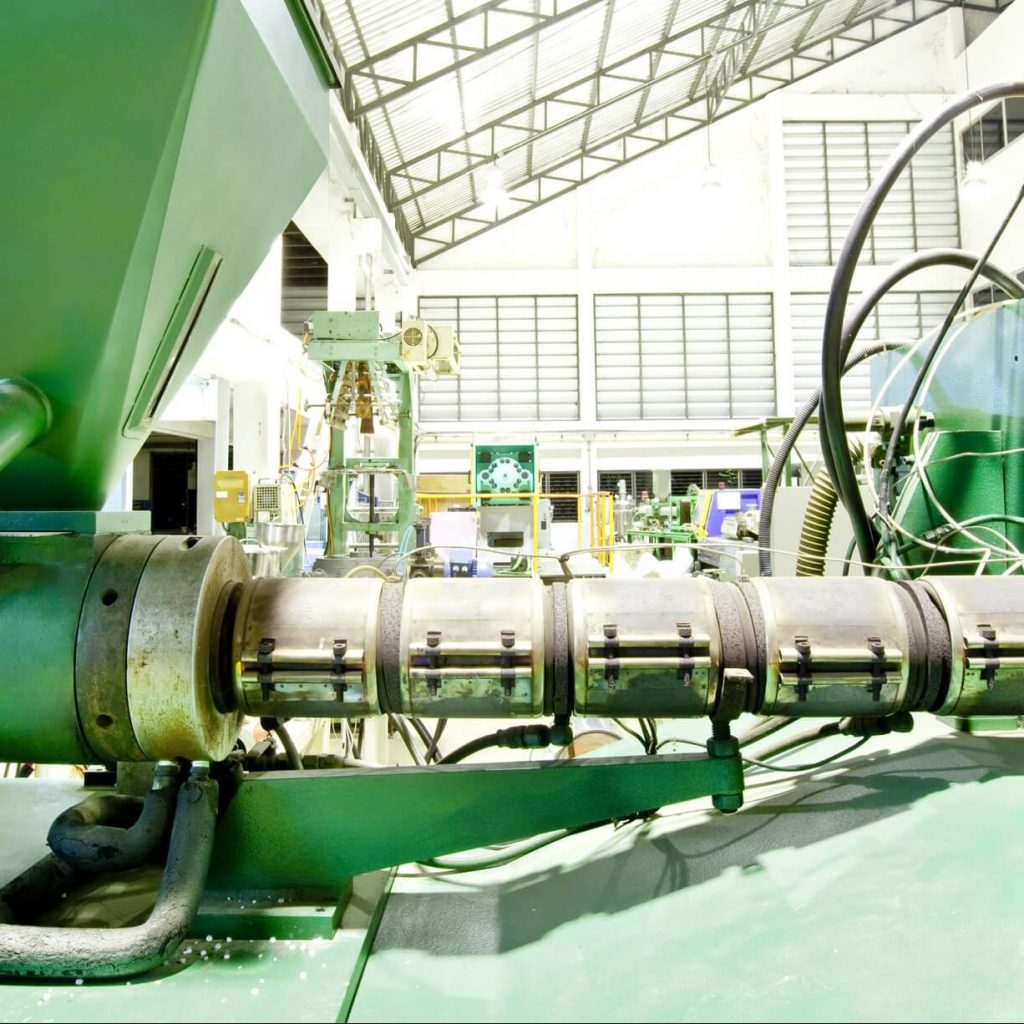

Passive and Active Heave Compensating Cylinders

Offshore Cylinder Experts

Apex hydraulics has over 30 years’ experience at the forefront of hydraulic cylinder design and manufacture. As well as designing bespoke hydraulic cylinders for fabrications across multiple sectors, Apex are able to improve on Original Equipment Manufacturer (OEM) design after cylinder failures; adapting failed cylinder designs to be longer lasting, more robust and able to cope with the rigours of a difficult environment. One such difficult environment is in the offshore sector, which presents a number of challenges with regard to the design and manufacture of hydraulic cylinders. A particularly complex branch of offshore hydraulic cylinder design is in that of Active and Passive Heave Compensating Cylinders.

What is a Heave Compensating Cylinder?

Heave compensating cylinders are utilised in applications where a cylinder is required to compensate for movement; such as the movement of waves on the ocean.

One such offshore application is for Compensated Coil Tube Lifting Frames (CCTLF) which are used to maintain the steadiness of the machinery when drilling out a pipeline for an oil or gas company. It is vital that the drill must remain steady in relation to the seabed.

Heave compensating cylinders are also used for offshore cranes, lifting items out of the water, while being buffeted by waves themselves. While there are specialised cranes that already incorporate a heave compensating cylinder, it is also possible to convert a standard offshore lifting crane into a heave compensating crane by installing a bespoke motion compensating cylinder.

The principal of a heave compensating cylinder is similar to that of a car suspension; but with the opposite function. On a car, the wheels move up and down to keep the car relatively still. A motion compensating cylinder keeps the tool still while the vehicle itself moves around.

Passive Heave Compensators (PHC)

Also known as a Drill String Compensator, there are two main types of PHC. The first type is without electronics and used for simple applications; it can perform either a splash zone crossing OR a simple subsea compensation task. The second type of PHC comes with an electronics package that allows the compensator to do multiple tasks by allowing manipulation of the internal gas pressure (which can be increased or reduced based on changing external influences).

Features:

- Capacities from 20 to 2000 tonne.

- Stroke typically 3 to 5 m.

- Common for all passive heave compensators are that they consist of a hydraulic cylinder and at least one accumulator. A valve package to control damping is optional.

- The size of the gas volume dictates the dynamic amplification that will be seen. Typically, it can be limited to static weight plus a few percent.

- Under normal circumstances, PHC cannot compensate for motion in air

Uses:

PHC are used to limit dynamic loads due to heave motion; for example, during a splash zone crossing. If a vessel goes up a wave, while trying to lift high resistance objects (such as suction anchors or big GRP covers) it risks the crane overloading due to the extra weight of water caused by the sudden change in lifting speed. In this way, the heave compensators act a little like a rubber band; allowing the vessel and crane to move without breaking the crane or stretching the cable.

With a PHC, the vessel can be disengaged from the item that it is lifting, allowing the sea to do the moving. The “passive” nature of the cylinder is that it is only compensating for the outside forces of the sea movement.

Active Heave Compensators (AHC)

Features:

- The compensator runs on a large battery pack. Due to energy regeneration (energy stored in the accumulators) the energy consumption is low.

- Capacities from 20 to 2000 tonne.

- Stroke typically 3 to 5 m.

- Motion reduction of above 90 % is easily achievable. Battery life of more than 12 hours is also easy to achieve.

- Can be made with redundancy in most components.

- Fastest design per 2019 is at 2.7 m/s.

Uses: AHC are used to eliminate heave motion of the payload both subsea and topside. For example, they may be used for systems where two different vessels need to be compensated – such as if lifting an item from one ship onto another. The two ships will go up and down at different points because they are on different waves. The challenge that the AHC is required to overcome is in how to lift something that is being dropped and lifted when the cylinder itself is also being dropped and lifted. Active Heave compensators have more control than PHC and are able to absorb unknown movement with very rapid responses.

Market Leading Heave Compensating Cylinder Repairs

Heave Compensating Cylinders produced by OEMs, while fit for purpose, often have shortened lifespans due to the complexities of the harsh offshore environment, such as the corrosion caused by saltwater and air. Apex hydraulics combines 30 years of expertise with manufacture and repair of cylinders, with an in depth understanding of the challenges of the offshore environment. This results in market leading designs including specialist seals, top spec coatings that can reduce corrosion, and unique mounting interfaces.

For more information on hydraulic cylinder manufacture or repairs for heave/motion compensating cylinders, call Apex Hydraulics on 01924 456788.

Gallery

Please find related images below…

Related Case Studies for Hydraulic Rams / Cylinders

Read more about our experience with hydraulic rams within the case studies below

Related Sector Experience for Hydraulic Cylinders / Rams

Read more about our sector experience associated with hydraulic cylinders below

Latest News

Read more about our latest news below