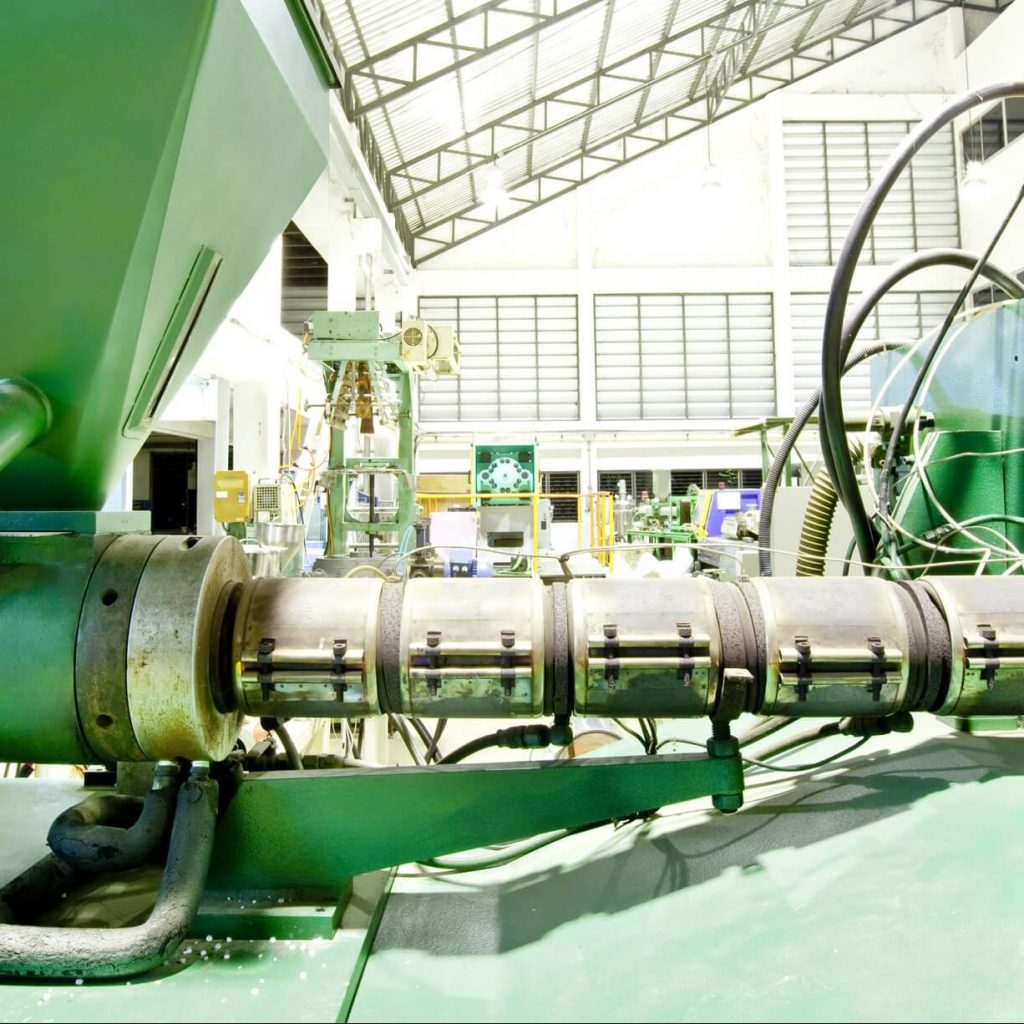

Hydraulic Cylinder Repair

We Are Yet to Find a Cylinder We Can’t Fix!

Expert Hydraulic Cylinder Repair

Sometimes referred to as a hydraulic ram, a repair to this expensive piece of equipment is significantly more cost effective than replacing with new. In most cases the repaired cylinder will be indistinguishable from a brand new model – particularly when you trust an expert team like Apex Hydraulics with any hydraulic cylinder repair work.

…in summary, maintenance is carried out at the most opportune moment to ensure performance and reliability is maintained and unnecessary maintenance, and potentially, down-time, drastically reduced

Our ability to assess the condition and life span of your hydraulic cylinder means that, over time, wear can be tracked. This allows us to determine the point at which maintenance should be carried out.

We then provide you with an efficient maintenance schedule which reduces downtime by identifying problems before they occur.

So in summary, maintenance is carried out at the most opportune moment to ensure performance and reliability is maintained and unnecessary maintenance, and potentially, down-time, drastically reduced.

What we Offer

We offer a free strip and quote service for hydraulic ram repair, and will do the following;

- Conduct a full assessment of the equipment

- Decide the best possible course of action

- Assess how many parts can be salvaged and

- Decide if it is cost effective for us to complete hydraulic cylinder repairs

All our cylinder repairs pass through six specialised departments

We offer a free strip and quote service for ram repair

Our Strip and Assessment department

This dedicated department enables your plant breakdowns to be dealt with quickly and efficiently.

Design Department

Our state of the art design department is available to improve and enhance the performance of your cylinders and we will always seek to improve your machinery when it arrives.

Our state of the art design department is available to improve and enhance the performance of your cylinders

We always carry a large stock of cylinders seals and other soft parts, which means we can offer prompt ram repairs. And, if we don’t carry the seals, our stores can usually purchase them for delivery within 24 hours.

Our Machine Shop

This is where we manufacture your cylinder component.

Our Fitting Shop

Our Fitting Shop is clean and well equipped so you can be assured your rams are assembled with the upmost expertise.

Our Inspection Dept

Once the rams have been assembled they are given a final inspection and tested according to our ISO 9001 Quality System.

Our Spray shop

The final stage of any high quality hydraulic cylinder repair is the paint spray which protects the cylinder from future corrosion.

We paint according to your exact specification, including the application of off shore and subsea paints.

Frequently Asked Questions…

Our turnaround time on cylinder repairs depends very much upon the complexity of the repair. However, we understand the impact of lost time on a company’s finances, so will work together with you to ensure as little downtime as possible. At Apex we are well staffed with qualified and experienced professionals who work quickly and efficiently. Our stores already have a huge array of seals and small parts. We have excellent relationships with our suppliers, so any products that we don’t have in stock can generally be sourced within 24 hours, ensuring a swifter repair process.

Yes, that won’t be a problem for Apex. We have a workshop that manufactures cylinders from scratch and so we can manufacture new parts where the originals are now obsolete. In many cases our team of designers will be able to improve on the original standards and design.

This is a common problem, and the short answer is; “yes”! Many hydraulic systems are fit for purpose when first purchased, but as a business grows, the fabrication may be used more and more, with the hydraulic system being worked harder than originally intended. However, with design tweaks from our team of specially qualified hydraulic cylinder design engineers, a cylinder can be made more robust in order for it to be used at a greater capacity.

As hydraulic cylinders are such large and complex pieces of equipment, in most cases repair will be far more economical financially than replacing with a new cylinder. However, there are exceptions. This will depend on several factors and we are happy to assess the costings for FREE in order to be able to give you a quote and help you to make a decision about whether repair or replacement is the most cost effective way forward for you. The experts in our strip and assessment department will dismantle your hydraulic cylinder, assess the extent of any damage and which parts need replacing or repairing before giving you a full quote for the repairs.

At Apex, we have the capability to repair all sizes of hydraulic cylinders; from small cylinders found in factory machinery, to huge cylinders used for steel manufacturing or the off-shore industry. We specialise in bespoke repairs and are happy to repair any cylinder that our customers present us with.

We often work with companies based all around the world; from as far as Australia and almost anywhere in between!

Yes, we are very familiar with working with third party insurers and should be able to provide any relevant certification that is required. We are happy to have visits from inspection agencies alongside our own robust inspection process if desired.

Unclean oil can be one of the principle causes of hydraulic cylinder breakdown and effective oil filtration can massively reduce breakdowns. Dirty oil can cause abrasions to the seals and other soft parts, which in turn can cause system failure and break down. We recommend a filtration unit that can be attached to working hydraulic systems, cleaning your oil and eradicating cylinder breakdowns caused by dirty oil. We offer a free test of our filtration units, in order for you to see the benefits for yourself.

Proud of our Quality Status

Our ISO 9001:2015 certification means we can focus on providing our customers with unbeatable technical expertise.

Our cylinders are market leading and have proven time and time again to surpass our competitors’ products.

Our capability stretches to testing on all fluids, including mineral oil, water, water glycol, synthetic fire resistant oils and rust inhibiting fluids.

Certification Available with Each Task Completed

Full ‘test and certificates of conformity’ are available should you need them.

We can also manufacture rams with third party approval certificates such as:

- DNV GL (Det Norske Veritas) DNVGL-CG-0194 (formerly standard for certification No.2.9)

- ABS (American Bureau of Shipping)

- Lloyds Register

- ISO 9001:2015

We can repair all your hydraulic and pneumatic cylinders from a small workshop ram, such as the Enerpac range, to enormous cylinders employed in steel foundries.

Some cylinders we see are now obsolete and therefore it can be difficult to purchase spares.

However, with our qualified design team and machine workshop, we can engineer the parts required to enable us to complete an effective cylinder repair.

Full ‘test and certificates of conformity’ are available should you need them.

We Are Yet to Find a Cylinder We Can’t Fix!

We can manufacture or repair rams to suit your individual requirements.

Here is a selection of the products we include:

|

|

A selection of the brands we service include:

|

|

Contact us today to learn more about our hydraulic ram repair services.

Related Case Studies for hydraulic ram repairs

Read more about our experience with hydraulic cylinder repairs within the case studies below

Related Sector Experience for hydraulic cylinder repairs

Read more about our sector experience associated with hydraulic ram repairs

Latest News

Read more about our latest news below