Launch And Recovery Systems (LARS) are an offshore system, used (as the name suggests), to launch and recover equipment into and out of the water. Usually mounted on the back or side of a vessel, they launch and retrieve a wide variety of apparatus, including Remote Operating Vehicles (ROV), diving bells and probes.

An ROV might weigh up to five tonnes and their deployment into the water is critical, for the safely of nearby personnel and for the protection of the ROV itself. They often contain an expensive array of tools, pincers, cameras or other equipment. Launching it into the water and recovering it back without damaging any of the equipment is carefully planned and executed.

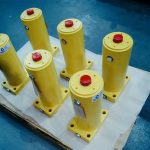

A number of different types of hydraulic cylinder are used within a LARS system:

- Tilt cylinders that are used for the pivoting acting – pivoting the frame over and back on board.

- Boom extend cylinders which are used to advance the product away from the side of the vessel.

- “Locking pin” or “latch” cylinders lock the frame in place when required.

- Motion compensating cylinders (also known as heave cylinders or pitch and roll cylinders) are used to try and counteract the movement of the vessel while engaging or disengaging the product. These cylinders work a bit like a spring, limiting the damage that happens while lifting out of the water as the boat rocks back and forward. These valve-controlled cylinders are likely to have one working side to side and one working front and back.

The LARS systems may be installed on a vessel for 20 years, but the harsh offshore environment means it is unlikely to continue to function for the entire time without needing a service. Once or twice during its lifespan it will be returned to the Original Equipment Manufacturer for repair. While the OEM repair controls and tests the fabrication, they will often send the hydraulic cylinders for independent, specialist repair and testing. For a number of years, Apex has been at the forefront of bespoke LARS hydraulic cylinder manufacture and repairs.

One of the most common failures for LARS cylinders is the rod coating. This may be due to general wear and tear from the harsh sea environments of salt, inclement weather and constant use. However, in addition, the OEM’s often find that companies have overworked the equipment. In one equipment failure it was even established that the equipment was being used completely outside of its remit – almost using it to tow equipment rather than to launch and recover.

The hydraulic cylinders are removed from their fabrication and shipped to Apex. When Apex receive the cylinders at their state-of-the-art Dewsbury factory, the cylinders go through a full refurbishment. They are initially dismantled in the strip and assessment area, so that designers and engineers can see where parts have failed.

Where parts have just failed through general wear and tear they will design like-for-like repairs or replacements to the parts.

Where relevant Apex may suggest improvements, particularly where the OEM specifies that it is likely to be used over its recommended loads. In these cases, Apex has a number of ways that it can make equipment stronger. There are restrictions in that the cylinder still needs to fit into the original envelope, but Apex designers and engineers are familiar with strengthening hydraulic cylinders within these parameters. In some cases it is possible to use a stronger steel to make the cylinder thicker in diameter, or to make a higher strength rod clevis. Parts are re-chromed or can be coated in Apex’s unique rod coating Corex. Corex has double the bond strength of Hard Chrome Plating, with over 10,000 PSI. The porosity is also far less at less than 1%, in comparison to HCP’s 5-10%. These features make rods covered in Corex far more resistant to pitting and cracking and impact, with some resistance to flex. This means that rods will last longer under harsh environments and extensive use.

Parts are manufactured in the machine shop and are reassembled by engineers in the fitting department. The cylinder is then tested to whatever pressure is required in the in-house testing department. As always, if required, DNV-GL or other third party approval can be facilitated, with third party witnessing of the testing welcome at any point in the process. Once testing satisfies the requirements, the cylinders will undergo shot blasting and offshore painting – usually three coats – required for protection as well as aesthetics. This can be done to NORSOK M 501 requirements if required.

As bespoke hydraulic cylinder designers with an excellent reputation for quality and service within the offshore industry, Apex Hydraulics are the ideal partner for the repair of LARS equipment. They are also well placed to design brand new hydraulic cylinders for OEMs that want a bespoke design for long lasting, robust Launch and Recovery Systems.

Related Products

The following products were utilised as part of this project. For more detailed information on these products, click on an image below…