Oil and gas companies invest many millions of pounds into offshore drilling in order to access raw fuel. This is predominantly done using an oil rig (with foundations on the seabed) or a semi submerged drilling rig (which uses submerged pontoons to stabilise the rig). Both are extremely stable structures, costing millions of pounds to hire for the drilling process. Once the pipes have been installed, the drilling equipment is moved elsewhere, leaving a vessel in place to extract as much oil and gas as possible.

After a time, the company may find that the well isn’t performing as well as they would want, or that there is another pocket of oil just out of reach. However, it is not practical or cost efficient to bring the drilling rig back again just to make hole a little bigger or smooth it out, so it flows more quickly.

Offshore companies are now responding to this niche requirement by offering the service of well enhancement. Specialist drilling tools work from small vessels that can improve an existing oil well by making it deeper or wider.

An impossible challenge?

These vessels are smaller ships; immediately removing the costs associated with building an entire drilling rig. However, doing any form of drilling from a floating object presents major challenges. In order to work effectively and safely, the drilling tool must be kept as still as possible. However, when placed upon a boat which naturally moves up and down with every wave, keeping the drill steady is a seemingly impossible challenge.

There are already companies that produce Compensated Coiled Tubing Lifting Frames (CCTLF) that have incorporated hydraulic or pneumatic cylinders into two sides of a frame, keeping the drill stable by removing heave motion.

However, many of the companies producing CCTLFs do not specialise in hydraulic cylinders, and so while they boast top spec designs, the cylinders themselves are not sufficiently durable to survive the rigours of an offshore environment. Apex was approached by a company that was using a leading brand of CCTLF but had found that the cylinders on this frame failed after 51 hours due to a corroded bore. The high speed of the cylinder stroke combined with no lubrication meant that the cylinders failed extremely rapidly in the corrosive sea air.

Apex Solution

These cylinders formed so much of the structure that they couldn’t be removed, so they had to be welded shut and abandoned. The tool already incorporated a power pack, so the real requirement was for an effective and long-lasting hydraulic cylinder.

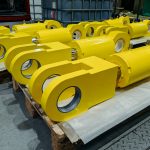

Apex produced a specialist, heave compensating cylinder to be attached to the CCTLF. With a six-metre stroke, this cylinder and the active hydraulic power unit can keep the drill or tooling still (relative to the earth) while the vessel it is mounted on can rise and fall up to 6m on the ocean.

The cylinder remains in a middle position on a calm day, with the Hydraulic Power Unit providing 150 tonnes of tension at all times. The HPU reacts to whether the ship is going up or down a wave – putting oil into the cylinder when it needs to retract and letting oil out when the cylinder needs to advance. This allows the cylinder, frame and tool to stay completely still relative to the seabed.

The system is essentially acting as a spring; albeit one that is completely accurate. The built-in linear transducer within the cylinder gives real time output on its exact position in stroke length to the controlling software. As the on-board accelerometer and motion reference unit sensors a wave, it quickly allows the HPU to respond by moving the cylinder in or out to compensate for the heave. This provides a cushioning effect and keeps the drill or tooling as still as possible in spite of the wave movements.

As the cylinder is only required to create a tension force, (needing to hold the CCTLF’s and coiled tube own weight) the oil from the HPU is only powered into the annulus side of the cylinder. This allows the cylinder to act fast enough in correlation to each passing wave. The full bore side of the cylinder has historically been open to atmosphere to ‘breath’ though this was the major downfall of the previous supplier’s designs. The Apex Hydraulic solution involved a large built in piston accumulator which allowed the full bore of the cylinder to be filled with oil, which during use was pushed into the accumulator, meaning the cylinder was now closed off completely from the sea air and harsh environment. With a complex internal design, nickel and hard chrome plated high strength rod, and internal pre-charged piston accumulator the cylinder is complex to meet its equally complex job and working conditions. During a standard campaign of around 1 month, the cylinder can advance and retract around 250,000 times.

When lifting the CCTLF from its horizontal position into its working vertical position it is important that the rod of the cylinder remains locked in place and doesn’t start extending due to its own self-weight, along with the weight of the lifting frame, coiled tubing and associated tools. It was therefore also a requirement of the cylinder that the rod can be mechanically locked in its closed position until the whole unit was lifted into position and pressure could be applied to tension the cylinder and remove the load from the lock. The cylinder and locking device were both designed and approved with DNV-GL as lifting devices, therefore they were mechanically pull tested in in a large mechanical frame along with DNV-GL witness.

The Results

The high-quality passive heave compensating Hydraulic Cylinder has improved this CCTLF to be a highly reliable tool in spite of the harsh sea environment that it is exposed to. The cylinder has already completed 2 full campaigns and will easily take on many more in the future.

The passive heave compensating cylinder has a 150-tonne safe working load and a 6m working stroke length. Complete with an internal linear transducer for positional readout, built in piston accumulator for the full bore capacity and the integrated rod locking device, this cylinder has it all. The cylinder and locking device is DNV-GL approved and load tested to DNVGL-CG-0194, DNV 2.7-1, API 8C, ISO 13535 and DNV OS-E101. Finished off with NORSOK M501 system 1 for long life protection.

Related Products

The following products were utilised as part of this project. For more detailed information on these products, click on an image below…