DNV 2.9 Type Approved Hydraulic Cylinders

Design, manufacture and deliver 4 bespoke Subsea Hydraulic Rams.

Our Work

DNV GL 2.9 Type Approved Hydraulic Cylinders

When it comes to meeting the complex requirements of clients within the gas and oil industry Apex have the experience, the technical expertise and the infrastructure to ensure that the solutions proposed will meet and exceed expectations. At Apex we pride ourselves on our ability to achieve short lead times without compromising quality and the bespoke nature of the task at hand.

As a result of Apex’s dedication to excellence and customer service they were recently approached for a second time by a satisfied client within the Gas and Oil industry.

This time the requirement was to design, manufacture and deliver 4 bespoke Subsea Hydraulic Rams.

Apex’s innovative design team got to work straight away making the necessary technical calculations and putting together an initial proposal to be submitted for customer sign off. After client approval Apex’s procurement team then set to work sourcing the best materials to hand over to the machine shop for manufacturing. Finally the completed cylinders arrived at Apex’s test and inspection team to undergo vigorous testing and final inspection before delivery.

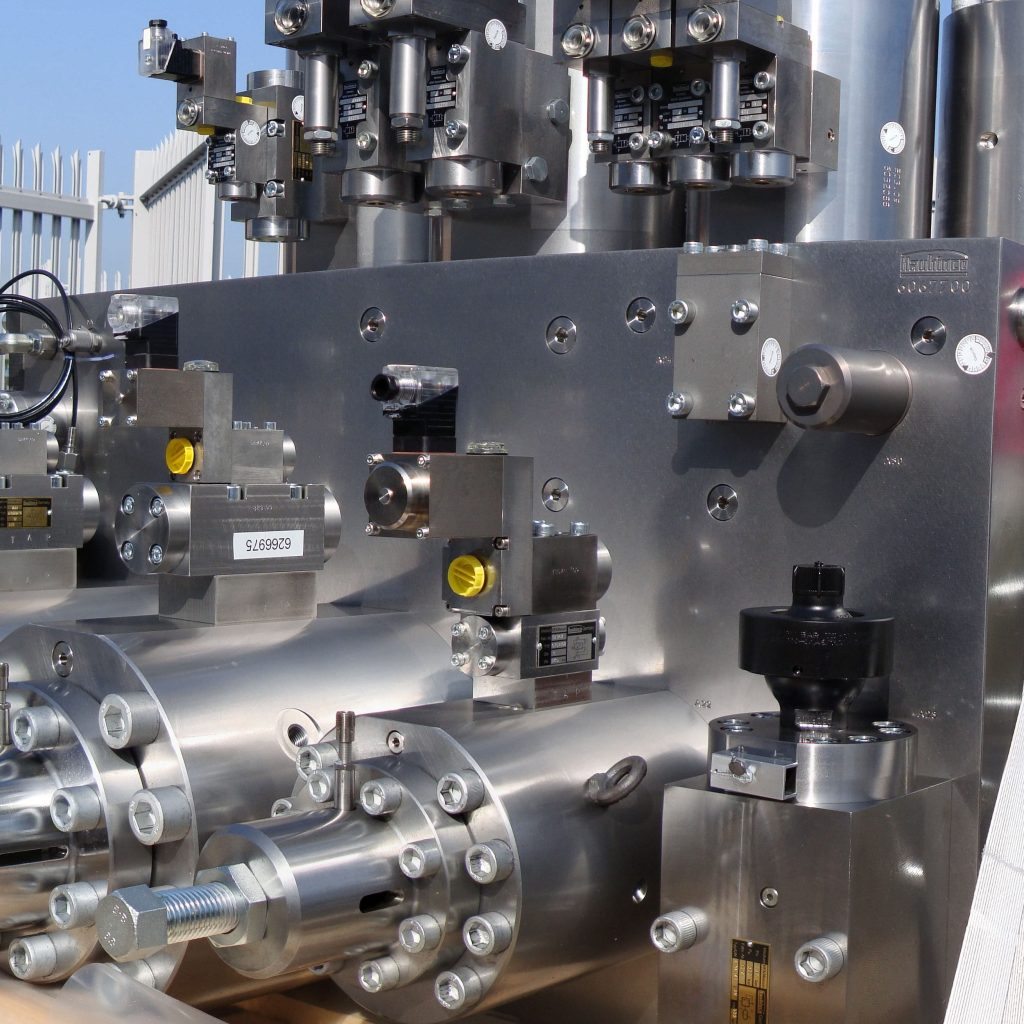

The result was 4 x offshore subsea cylinders 17-4PH H1150+1150 incorporating Stainless steel rod and cylinder, Stainless Steel carry handle, a COREX coated rod and double acting hydraulic cylinders – designed with DNV 2.9 type approval.

The final product from initial consultation to delivery was just 54 days

COREX Apex’s superior alternative to Hard Chrome coating (HCC) has been designed specifically for use in the Gas and Oil industry where arduous conditions mean essential components suffer extreme abrasive wear and corrosion under great environmental pressures and continuous usage. COREX’s extreme hardness 1400Hv and thicker coating ensures increased cylinder life, durability, efficiency and performance. COREX therefore enables machinery to cope with low lubricity fluids or high contamination better than its counterpart HCP. COREX’s extreme hardness, up to 1400Hv, provides excellent bond strength of <10,000psi compared to HCP 750-850HV, <5000psi. COREX more than halves the impact damage to cylinders through small repeated impact and large impact, which dents the substrate and in turn leads to cracking and peeling of the coating.

The final product from initial consultation to delivery was just 54 days. Apex’s impressive lead times, cutting edge technologies, skilled engineers and commitment to client satisfaction is the backbone of Apex success and repeat business.

The Sectors

We have strong experience working across a variety of different sectors. If you would like to read more about our sector experience associated with this project – click an image for more information….

Related Products

The following products were utilised as part of this project. For more detailed information on these products, click on an image below…

Related Services

The following services were utilised as part of this project. For more detailed information on these services, click on an image below…