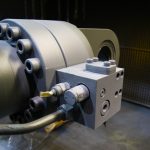

Cylinder Manufacture

7 Metre stroke cylinder made to tight deadline

Our Work

Apex Hydraulics helps to save a recycling yard valuable time, money and convenience with a speedy repair turnaround.

We were approached to investigate a damaged cylinder. The recycling yard had been quoted a lengthy and expensive lead-time from its original equipment manufacturer and hoped we might be able to help.

The Cylinder’s (7 metre stroke – 210mm rod – 250mm bore) piston was severely scored and dented due to the continuous heavy impact of scrap metal. The impact caused seal damage and created oil leaks, all of which meant that over time the equipment would lose efficiency and the customer money.

Not only that but as the problem became progressively worse, we knew if the equipment was not replaced quickly, it would lead to contamination and complete system failure.

Apex put its technical engineering team onto it and were able to source the materials, manufacture the parts, assemble, test and paint within a speedy three week period. And it provided the customer with a cost saving as the Apex manufactured cylinder was approximately 70% of the original equipment manufacturer.

The customer was delighted with the results and Apex Hydraulics is now their first port of call for any repairs or servicing requirements.

The Sectors

We have strong experience working across a variety of different sectors. If you would like to read more about our sector experience associated with this project – click an image for more information….

Related Products

The following products were utilised as part of this project. For more detailed information on these products, click on an image below…

Related Services

The following services were utilised as part of this project. For more detailed information on these services, click on an image below…